Idaho Print Cleaning

Cold Jet dry ice blasting has resulted in optimal equipment performance and increased productivity in the Printing Industry. Cold Jet dry ice blasting systems allow lengthy cleaning processes to be shortened by on-line precision cleaning. Ink buildup on the gears and deck guides causes poor alignment and results in low print quality and high scrap rates. Cold Jet dry ice blasting can reduce or in some cases eliminate low quality and high scrap rates. In many plants, the cleaning of the side frames and print deck mechanism is usually avoided until absolutely necessary.

Typically, several hours are spent on each color station to scrape and wipe the critical surfaces. With today’s modern presses having six to eight color decks, cleaning downtime can easily add up to several thousands of dollars of lost production per cleaning cycle. However, when using Cold Jet dry ice blasting, because the cylinders can be removed to provide easy access to all surfaces, both sides of the deck can be cleaned in as little as 10-15 minutes before going back into production. In addition, dried out drip pans and fountains can easily be cleaned as well. Printing with fluid inks at high speeds also creates an “ink mist” of fine droplets that comes from the splitting and transfer of the inks from the printing plate to the substrate being printed.

These droplets settle on the “between color dryer boxes” and eventually clog the vent slots or nozzles, resulting in a reduced and uneven airflow, which in turn inhibits proper drying. To compensate for this reduced airflow, the press speed is reduced, which immediately results in lost production and lower quality. Not only does Cold Jet dry ice blasting speed up the cleaning process, but it cleans better too. In a typical cleaning process, manual scraping requires 20-30 man-hours per piece of equipment. Using the Cold Jet dry ice blasting process, the same piece of equipment was cleaned in less than two hours. With this type of speed and efficiency, there is no longer any need to wait for the next shutdown to clean. It is now cost effective to do your cleaning between job changes on the press, giving you more production time and higher production rates. Cold Jet dry ice blasting replaces the use of dangerous solvents, scrapers, chisels and emery cloths without having to dismantle the press thus eliminating many direct and indirect costs such as downtime hours, poor printing quality, increase scrap, wear of machined parts, and disposal of hazardous waste and solvents.

See Dry Ice Blasting Solutions in Action

Grippers / Rollers

Drums

Ink Trays

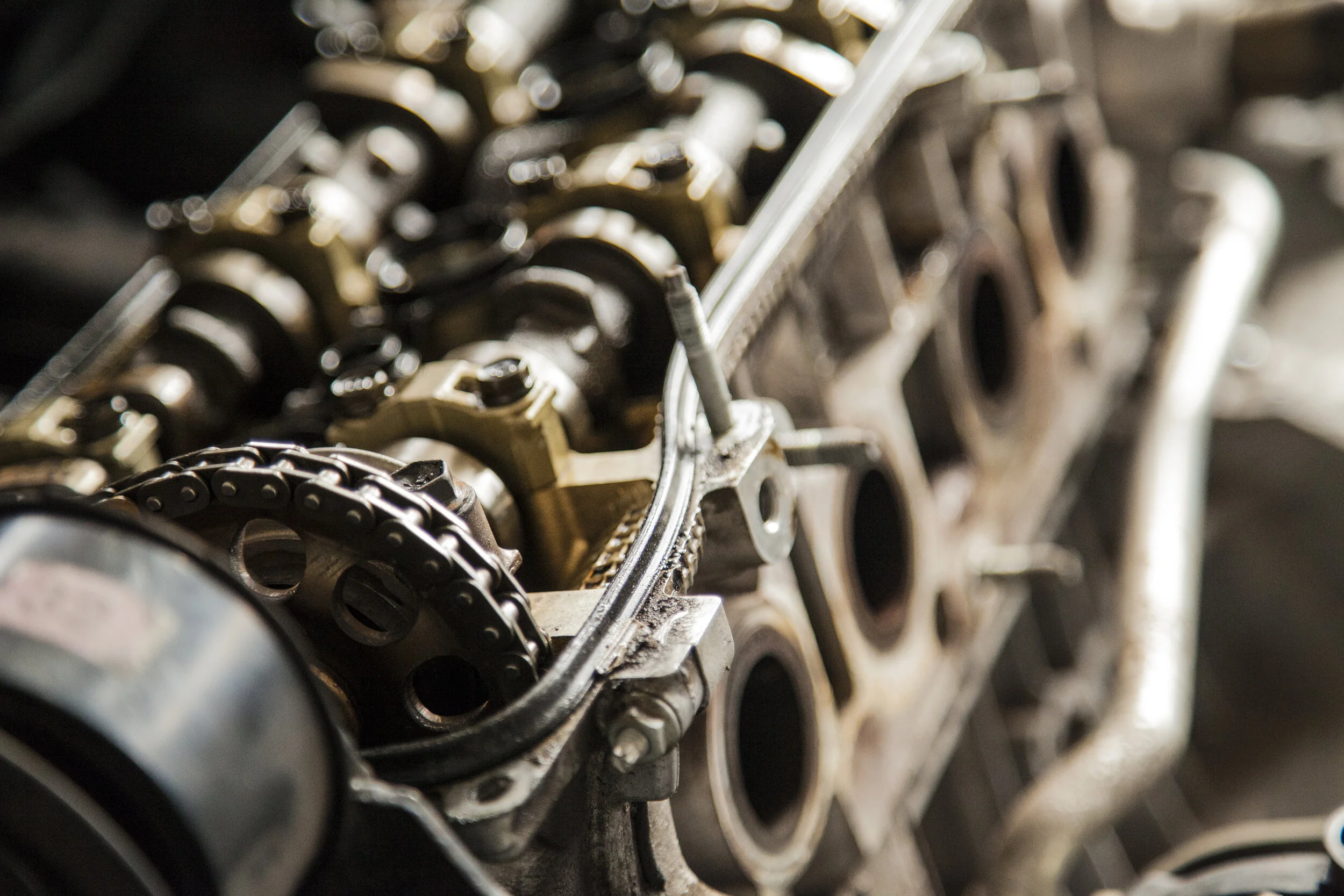

Gears and Deck Guides

Side Walls

Feeder / Delivery Units

Letterpress

Flexography Gravure Presses